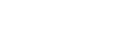

Rolling Process

Rolling Process

Rolling Process

The rolling process reheats billet and then places them between two rolls and stretches or shapes them into thin metals by applying continuous force as the space between the rolls is gradually narrowed. The billet cast by an 800,000-ton electric arc furnace and high-tech continuous casting machine go through the precision rolling mill and is made into reinforcing bar.

Reheating Furnace

This is a process that reheats the billet produced from the rolling process to facilitate rolling. It reheats the billet between 1050°C and 1100°C.

Rolling

The cross-section of reheated billet is continuously minimized according to the pass schedule using 2 rolls (two-high rolling mill) and shaped into various forms. The reheated billet typically goes through 10 to 16 passes depending on the product.

Adjustment Process

In this process, each product produced through the rolling mill is cut and packaged according to the packaging unit by specification. Our company is equipped with a counter machine for automatically measuring the package quantity of products and small and large binding machines for convenient use.

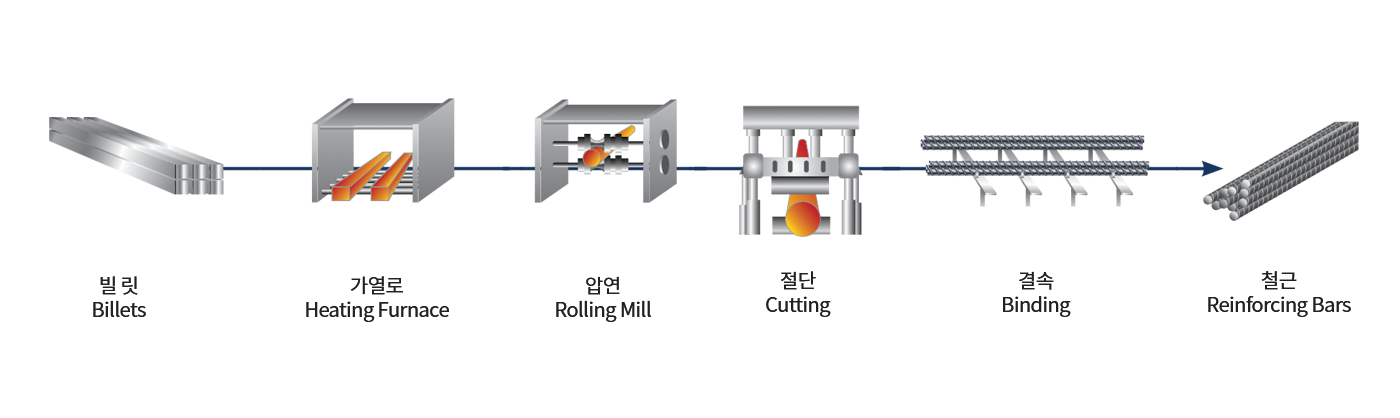

Tagging & Loading

The produced reinforcing bar is stored at the open-storage yard after it is tagged.